One Can 3D Print Almost Anything:

a Car, an Elegant Dress or an Arm Prosthesis.

So What?

Helena Dodziuk

E-mail: dodziuk10@vp.pl, hdodziuk@ichf.edu.pl

© Helena Dodziuk

Fig. 1. M200 printer of Polish company Zortrax, which was classified as the best in its category by the 3d hubs site. © Zortrax.pl

3D printing is not new; there was an opinion expressed on the Internet that this method was patented in the 1970s. The term was first applied by Prof. Ely Sachs of MIT (Massachusetts Institute of Technology) in 1995. In industry until recently this method was used almost exclusively for preparation of tools and prototypes. However, we are now at a crucial time in the development of this method of production. Not only it is beginning to be used by individuals (at the moment mainly in the USA, UK and some other countries – the list is rapidly expanding), but it is now also beginning to be used on an industrial scale by large corporations. Until recently it took a very long time for great revolutionary inventions to find applications that changed lives of masses. Today, the rapidly developing method of 3D printing not only offers numerous marketed applications but promises to bring much more in the future and its influence on society is hard to grasp. The technique earlier used mainly to build tools and prototypes, is now being transferred to mass production by big corporations: General Electric, Ford, Mattel, Airbus to name but a few. The first fully 3D printed car Strati is worth mentioning here, too. Remarkably, it took four years to design it but only 44 hours to 3D print a driving prototype.

Fig. 2. Strati car printed by the Local Motors company. © Local Motors.

This manufacturing method expands into various fields offering, for instance, prostheses adapted to individual patients in medicine, replacement parts for washing machines or refrigerators that ordinary people can make themselves. Files for the 3D printing of some such parts can be downloaded for free from the Thingiverse site. Fabulous 3D printed dresses, shoes (Fig. 3) or jewelry evoke admiration. We will discuss such applications below in more detail.

Fig. 3. A shoe designed by Julian Hakes shown at 3D Print Show 2015 in Berlin. © H. Dodziuk.

3D Printing and its advantages

3D printers operate in a way similar to popular ink-jet printers but instead of ink they use plastic, metal, organic or other material extruded from nozzles. The basis, the design, is created by a computer-aided design (CAD) method or by 3D scanning. Today you can 3D print from your laptop, smartphone, tablet or regular PC equipped with a scanner. The design has to be submitted to the printer in form of slices of 3D object to be printed. The orientation of slicing is one of the most significant manufacturing decisions that cannot be computerized or automated but has to be made by engineers. The thickness of slices, typically, 0.1 mm for polymers and 30 µm for metals is determined by the type of 3D printer and the material involved. The layers corresponding to slices of the 3D pattern are printed successively, solidified and the layers are fused together. After each step, the work surface is lowered by the thickness of the layer to allow for the next layer to be printed. This prevents warping of the material.

It should be emphasized that the 3D printing, also known as the additive manufacturing, is fundamentally different from the classical method of subtractive manufacturing involving the use of tools such as lathe or milling machines, which form the desired element by removing unnecessary material from the block. The Wikipedia defines 3D printing as production of three-dimensional objects of any shape on the basis of a digital model.

What can be used as 'ink'? Polymers, metallic powders, rubber, sand, carbon fibers, organic materials (for example, cells and wood but also chocolate), mixtures, almost everything.

Watch the 3D printing on YouTube.

3D printing has several advantages over the traditional methods of manufacturing.

1. 3D printing offers possibilities of manufacturing in a single run of very complicated shapes which are difficult to make by conventional methods. You cannot make as one piece the model of astrolabium presented below (Fig. 4). A 3D printed jet engine nozzle made by General Electric, which is currently investing heavily in large-scale use of this technique, is a good example. Such a nozzle, which traditionally is composed of 20 and has a very complex shape, is printed as a single piece. Moreover, such a nozzle is lighter than the conventionally produced, so that the engine equipped with it consumes 10% less fuel and produces 10% less emissions.

Fig. 4. A model of an old astronomical instrument, astrolabium, with movable inner circles printed as one part. © H. Dodziuk

2. Considerably lower costs associated with the development and manufacturing of production tools, as compared to conventional methods.

3. Avoiding loss of material typical of conventional methods such as, for example, machining. It has been proposed to use waste as the 'ink' for printing (waste1, waste2). However, 3D printing can have also undesirable environmental effects.

2. Lower costs associated with the develpement and manufacturing of production tools, as compare to traditional methods.

3. Avoiding loss of material typical of conventional methods such as, for example, machining. It has been proposed to use waste as the 'ink' for printing (waste1, waste2). However, 3D printing can have also undesirable environmental effects.

4. Low cost and speed of prototype testing allowing for fast corrections and improvements.

5. Of numerous applications of 3D printing in various areas, the most exciting seem to be those in medicine allowing for prostheses exactly matching the patient’s size (e. g., brain powered prosthetic arm, lower jaw, or cranial implants), bioprinting using cells to speed up healing wounds and printing organ tissues to evaluate toxicity of drugs. An exciting proposal, already put into practice, consists of using models of the patient’s brain or other organs, obtained on the basis of MRI or other techniques, to allow surgeons to train for future operation.

Fig. 5. Prostheses for the African war victims made by Not Impossible company. © Not Impossible.

6. So far, 3D printing is cheaper, faster and more flexible than traditional production only for short production runs. This may soon change with the rapid decline in the cost of 3D printers and increase speed of the printing process.

7. The advantage of the printers, which from the point of view of the social costs may prove to be a disadvantage, is that they can work 24 hours a day, 7 days a week depriving workers of their jobs.

As illustrated by several design projects, e.g. MATHART by Disingof, programs for printing prostheses for amputees in Asia and Africa who lost their limbs during the fratricidal wars (the Not Impossible and 3D Life Prints projects), 3D printing not only stimulates imagination but also changes our world. 3D printing introduces several added values. As mentioned earlier, the printed aircraft parts are lighter than those manufactured using traditional methods and that 3D printing allows one to produce individualized prostheses. Such additional advantages of 3D printing are numerous. Some of them will be presented later.

Fig. 6. One of the fascinating MATHART Dizingof projects. © Dizingof

Industrial applications of 3D printers

Industrial applications of 3D printing are numerous. At present, we are at the beginning of a rapid development of industrial applications of this fabrication method, which will introduce significant changes in industry and beyond. Displacement of workers by 3D printers was mentioned above, but the societal changes will be much broader and are difficult to grasp today. Few years ago the respected The Economist published an article entitled „Print me a Stradivarius” with a photo of 3D printed violin on the cover.

Listen to music played on such an instrument on Violin. There are more than ten such links on the YouTube, and one of the instrument has a fascinating shape strange violin. Another instrument of this kind was recently presented by 3D Varius company.

In the article, the future influence of 3D printing on economy and everyday life was compared to those of the impact of printing press, steam engine and transistor. At present, a full effect of 3D printing cannot be estimated. However, it is expected that it will bring significant changes in several areas and companies, enterpreneurs and lawyers will be forced to adjust to them. Today we are at a fascinating moment, when 3D printing, earlier applied to manufacturing of tools and prototypes, enters mass production at General Electric, Ford, Siemens, Mattel, Airbus, and other companies. This process will certainly intensify.

Great efforts are underway to develop less expensive, faster and more specialized 3D printers and printing materials. We mentioned the fully 3D printed Strati car above. Airbus’ efforts to develop gigantic 3D printers for manufacturing airplane parts and GE studies of printing nozzles of jet engines are few published examples that I could find. I am certain many more are being developed in secret by various companies. However, recently a news was published that the new Airbus A350 XWB contains more than 1000 3D printed parts.

3D printing is expected also to revolutionize spare parts management. Today repair shops store all spare parts needed, in the near future they will have a 3D printer and files of the parts saving huge costs of the storage. American army used 3D printers in Iraq and Aphganistan instead of bringing the complete sets of spare parts there.

3D printing is now a hot topic for many engineers, tinkerers, fans of DIY, scientists, and even hackers. They develop new, cheaper and/or specialized printers for numerous applications, novel materials for printing, as well as new, exciting applications, including those in regenerative medicine, construction, aerospace and space research, fashion, food industry to name but a few.

Fig. 7. Chocolate globes 3D printed by the TNO company. © TNO.

Free open-source software (FOSS), free open-source hardware (FOSH), and self-replicating 3D printers

Everyone knows about open source software, such as Linux. A new element in the development of 3D printing (and many other areas) is the use of free open-source hardware. This significantly expands the capabilities compared with using only free software. On RepRap website, one can build a 3D printer, for example by retrieving data from webpages, using Arduino or Raspberry Pi microcontrollers and FOSS free software. One can also design and make 3D printed laboratory instruments. This opens up completely new perspectives difficult to grasp. Or example, Cronin’s group is building systems for carrying out and monitoring chemical reactions yielding very interesting, sometimes surprising results2. Some of them will be described below.

A flood of applications – something new every day

In the beginning of the twenty-first century, engineers and designers began using 3D printers intensively to quickly and inexpensively build tools and prototypes that are now widely used in various industries. As mentioned earlier, the Strati car has been recently 3D printed similarly to nozzles of next-generation jet engines readied for production by GE. Multiple applications of 3D printing are now increasingly being introduced in many fields: architecture, medicine and dentistry, food, jewelry industry, education, and many others, not only for prototyping, but also for medium-scale production. Moreover, as I mentioned in the beginning, large corporations have started programs for implementation of three-dimensional printer for mass production. On the Internet one can find many interesting prototypes, such as printed motorcycle, jewelry, bikini or fragment of Nike shoes. I saw printed in 3D bike at the Museum of Contemporary Art in Krakow in the Polish-British Exhibition of Sustainable and small prewar sculptures (printed in 3D on the basis of preserved drawings) by Polish artist Janek Simon shown at the exhibition in the Polish Zachęta National Gallery.

Fig. 8. Copies of small prewar sculptures (3D printed on the basis of preserved drawings) by Polish artist Janek Simon. © Zachęta Gallery

See also fascinating dresses and shoes (in Polish). A corset shown at the 3D Printshow in 2015 in Berlin presented below (and the shoe shown in Fig. 3) is an example of an attractive 3D printed dress.

Fig. 9. Corset designed and 3D printed by Michaella Jansen van Vuuren. © H. Dodziuk

Applications of 3D printing in medicine

The most interesting applications of 3D printing are probably in the domain of regenerative medicine, such as denture teeth or bones that exactly match patient's body. For instance, an 83-year-old cancer patient with large changes in the lower jaw received the 3D printed implant matching exactly her anatomy. Similarly, a seventeen year old (at the time) American high school student Easton LaChappelle built a girl’s hand prosthesis, whose movements were controlled by brainwaves since he felt sorry that the girl’s parents could not afford the new, larger prosthesis for $ 80 000. The prosthesis that Easton built costs less than $500. Surprisingly, this drew attention of managers of the Dutch company Heineken for quite a different purpose; they wanted to order 500 artificial arms to offer beer in pubs. Currently Easton LaChappelle has a job at NASA on the Robonaut project. He has also founded a company Unlimited Tomorrow, Inc. and seeks funding on Kickstarter for his new, more functional prosthesis and on gofundme website for a new exoskeleton that he develops to help paraplegics walk again.

Fig. 10. Hand prosthesis from the Open Bionics company founded by Joel Gibbard. © H. Dodziuk

Numerous and very inexpensive limb prostheses completely changed the situation on this market: instead of ca. $100 000 they can cost less than $1000. Their appearance also has changed dramatically; kids and teenagers do not want their prostheses to mimic e. g. a hand, it should be an attractive gadget instead.

Another example of 3D printed prosthesis is the artificial ear created jointly by scientists and doctors from Cornell University. As the ‘ink’ for printing, they used a gel, which consisted of live cells, collagen isolated from rat tails and ear cartilage obtained from cows. In this case, the collagen was used as a scaffold, on which the cartilage and cells were deposited. A full safety inspection of the procedure used may take three years. It will then be possible to use it for patients who lost all or part of the ear in an accident or as a result of cancer or who suffer from congenital ear deformity called Microtia.

One of the greatest achievement in the area of the applications of 3D printing in medicine are bioprinters (also called organ printers or computer-aided tissue engineering devices)1. They will remove the limitations or perhaps even eliminate the use of human donors in the future. Two years ago a patient cured of cancer received a new face, a part of which was 3D printed.

Fig. 11. A patient cured from cancer shows a face prosthesis, a part of which was 3D printed. © Geoff Pugh

There have also been reports of printing of liver tissue and artificial kidney. However, obtaining blood vessels in this way is much more difficult. Even present day modest printing capabilities of human organs permit modeling of the patient's heart to make a model using medical equipment of appropriate size so that it can be used for the operation on a specific person, for instance a baby or even a fetus in the womb. Similarly, as mentioned above surgeons practice complicated operations on 3D printed models, e.g. of of kidney (in Polish). New stunning three-dimensional printing applications in medicine appear almost daily.

3D printing can also be used in synthesis and testing of drugs. Chemical synthesis of various substances including drugs using 3D printing was reported by Dr. Lee Cronin group whose work will be discussed below2. As concerns testing, Dr. Anthony Atala is a leading specialist in bioprinting, i.e. in 3D printing of layers of cells with artificial scaffolding1. This method allows one to obtain miniaturized and simplified versions of human organs, which can be placed on a chip and supplied with a blood substitute. Such models of human bodies could also be used to study human response to new drugs as well as to dangerous diseases or chemical warfare agents such as sarin gas. Researchers may be able to avoid in this way animal studies or experiments on human cells. The first such lab-on-chip device consisting of a liver assay for drug testing has been recently approved by American Food and Drug Administration after impressive testing that showed toxicity not only to known toxic drugs but also of the drugs that were first accepted for use and then removed from the market in view of the earlier undetected toxicity.

One of the most recent inventions, in use of 3D printing in medicine is a "biopen", i.e. “a pen” that accurately applies cells on a wound leading to a much more rapid regeneration of tissue.

Applications of 3D printing in research will be presented only briefly. Recently Dr. Gabriel Villard and his colleagues from the University of Oxford obtained 3D printed tissue, allowing them to obtain an artificial model of the intercell communication. This is a significant improvement over the existing cell models, where intercellular cooperation is impossible. Interestingly, some of the objects created by Villar et al. change their shapes after being printed. A similar phenomenon was observed later and called 4D printing, adding time as the fourth dimension. Villar Group has also developed a method that allows the introduction of new natural or synthetic biomaterials into living cells. This in turn would allow the study of completely new phenomena.

The work of Dr. Lee Cronin and colleagues from the University of Glasgow in the field of chemical synthesis using 3D printing2 attracted great interest. They have developed and built equipment to perform chemical reactions and analyze the products obtained using this method of preparation. These researchers have received in their sets new organic and inorganic chemicals and proved their structures also using these kits. According to Dr. Cronin "This approach is inexpensive, automated and modifiable chemical platform, which allows the use of methods of chemical engineering at the typical synthetic laboratories." Then experimenting with 3D printing Cronin group created within a few hours (using inexpensive materials) a number of reliable and durable miniaturized liquid reactors for chemical synthesis. Unfortunately, these scientists are also examining the possibility of printing medications (currently ibuprofen), which for obvious reasons are interesting not only for pharmaceutical companies or the generals of NATO. It seems that Dr. Cronin definitely does not take into account the legal, medical and practical problems associated with these studies. He says he cannot imagine the gangsters 3D printing drugs. Being aware of the serious problems of counterfeiting of drugs and the abuse of common medicines without control (problems of addiction), I consider the views of Dr. Cronin as naive and its activity in this field irresponsible. However, I must admit that American FDA has recently approved the first 3D printed drug.

Fig. 12. 3D printed models of crystal structures and molecules3.

What is new in 3D printing?

Almost daily there are new and exciting developments in 3D printing. As mentioned above, 3D printing applications expand rapidly. The technique was used first for making tools and prototypes, and now they enter into production on a large scale by major corporations such as GE, Ford, Mattel, Airbus, Lockheed Martin or many emerging companies such as korecologic. Srinivasan and Bassan already in 2012, claimed that "There are good chances that you already flew the plane, not knowing that it was built using some 3D printed parts, which were lighter and used less fuel."

For several years, work has been underway on the use of 3D printing in construction. Behrokh Khoshnevis from the University of Southern California built in his company the Contour Crafting Contour Crafting printer, with which you can build a house with an area of over 200 m2 in 24 hours with all the cables and pipes incorporated during printing. The Netherland Canal House Project has to be mentioned, too. Recently, an announcement came out of China that, as an experiment, they built 10 houses using the waste materials. Although most of the building projects are in development, you can buy today a 3D printer that will print a house za 12 000 dolarów amerykańskich.

Increasingly complex and inexpensive implants and prostheses are being developed and chances are that 3D printing may one day reduce or even eliminate the shortage of organs available for transplantation by creation of organs aimed precisely at the patient needs. As mentioned before, an important factor is the drastic fall in prices of prostheses. We should mention here also special programs (Not Impossible, 3D Life Prints) devoted to producing printed in 3D prostheses for the victims of the wars in Africa (Fig. 5) and Asia.

Of course, the use of 3D printers will be accompanied by product differentiation tailored to a specific customer. This tendency is well illustrated by the small gadget, personalized Iphone case, showing exactly how the production of the product according to customer requirements provides innovative companies a competitive advantage. Among others, the most important manifestations of adaptations to the client (patient) are individualized medical applications discussed previously, such as prosthetic arm controlled by brain waves and facial prosthesis partially printed in 3D (Fig. 11). One can challenge some of Alvin Toffler forecasts expressed in his visionary "Future shock", but his announcement of the era of personalized products fits well with the trends in 3D printing4.

Using a specialized 3D printer, the Stratasys company produced multilayer fabric consisting of a standard plastic fibers separated by layers of "smart materials". This fabric has been able to absorb water, allowing it to spread to the whole structure that can be bent or twisted by another intelligent layer. This new concept allows for experimentation with materials, energy sources and the design details of devices thus enabling new applications.

Thanks to the steep decline in prices and to much better software as well as development of specific printers and materials for printing, 3D printing develops rapidly. Both professional and amateur designers have greater access to printers, significantly expanding their capabilities. They are able to print their three-dimensional object already in the design phase, modify it and re-print, which will accelerate the pace of innovation.

A year ago, it was expected that 3D printing workshops will soon appear everywhere. Today such printers are gradually introduced into schools where they trigger creativity and imagination of young users. The shops and workshops pop up everywhere. The elegant London department store, Selfridges, opened a stand with 3D printing in October 2013. The supermarket Albert Hejin in Eindhoven, Holland, has launched an experimental stand printing sweets, which enjoyed such great success that now it operates permanently.

Fig. 14. 3D printed cakes by the Zmorph company. © Zmorph.

The combination of new materials and printed electronics at the nanoscale is expected to create new products with properties previously unimaginable liberating creativity of engineers and designers. On the other hand, the ease of copying such objects will ignite vigorous debate on Intellectual Property Rights. The controversies will be similar to those initiated 10 years ago by websites sharing files, such as FilesTube and Shared allowing copying and sharing of music.

More than 3D: time as the the fourth dimension

Mr. Jourdain of Molier’s play "The Bourgeois Gentleman" did not know that he spoke in prose. Similarly Dr. Gabriel Villar and his colleagues, whose work we discussed above, did not know that their 3D printed objects changing shape in time, are examples of four-dimensional printing. Just as in the theory of relativity, time is the fourth dimension in addition to the three spatial ones. Dr. Skylar Tibbits from the Self-Assembly Lab at MIT took advantage of the power of self-promotion and presented 4D printing at the 2013 TED conference in Los Angeles, the United States, although the same phenomenon that has been observed and proposed for use earlier by Dr. Villar and coworkers went unnoticed. The application of 4D printing will take time, but it will create new opportunities, e.g. in the case of objects in hard to reach places such as underground water pipes. It might be possible to significantly expand or reduce the water flow thus avoiding excavation necessary to replace the pipes. Other proposed applications of 4D printing are self-organizing furniture, vehicles, and even buildings. It is anticipated that 4D printed objects will be used for performing repairs in places that are hard to reach or dangerous for humans such as in nuclear reactors or space stations. On the other hand, I do not understand why 4D printing is to be used for furniture production.

What next?

The price of a printer depends, of course, on a specific printer, its purpose and the quality of output. However, with ever-falling prices (from US $ 1,000 at the beginning of 2013, and now down to US $ 100 for a DIY printer kit) on the one hand, and the availability of easy to assemble RepRap printers, and the like on the other, 3D printing becomes available for almost everyone. Availability of 3D printers is gaining momentum: the printers become available in schools (China plans to introduce printers into the elementary schools), shopping centers, or simply in the streets (see, for example, the Kiosk project).

As we mentioned above, the 3D printing applications are migrating from prototypes and small-scale printing to large commercial applications. Recently, we have learned that a new Airbus A350 XWB airplane contains more than 1000 3D printed parts. Several companies (GE, Airbus and Lockheed-Martin among other) are investigating the possibility of building much larger aircraft components using giant 3D printers. In addition to the reduction or elimination of waste, reducing fuel consumption in cars and airplanes, 3D printed parts will also affect the environment, resulting in, among others, lower exhaust emissions. On the other hand, some people are warning that the ease of printing may result in impulsive and ostentatious consumption.

In the near future a solar powered open-source 3D printer will soon appear. The printer with such power supply was used by Markus Kayser to make glass (that perhaps due to the appearance would be called ceramic) vessels in the desert.

Fig. 15. Solar Sinter project by Markus Kayser: the 3D printer powered by solar panels (left) and the printed dishes (right)

Printing food: NASA invested $ 125,000 in a project to develop a 3D printer that will print pizza. Recently, two companies launched professional 3D food printers named Foodini and ChefJet and ChefJet Pro, for manufacturing chocolates and sweets. However, the food that can be printed may be hard to swallow, although the idea has strong support in some quarters.

Pot-pourri of ideas

Creativity knows no bounds. If you want to have a three-dimensional model of your unborn child, the Japanese company Fasotec will print it for you. Building that mimics the Möbius strip has been proposed. In the US, a start-up Modern Meadow has been founded aiming at production of raw meat with bioink containing different types of organic cells. One of the best-known Silicon Valley investors Peter Thiel, co-founder of PayPal and early investor in Facebook supports this endevour. Recently, a humanoid 3D printed robot and drone (you can print for yourself) have been reported. There is no end to new ideas.

What about printing your own drugs or weapons?

Not all perspectives of 3D printing are acceptable. We already mentioned the controversial idea of Cronin of printing drugs at home. The possibility of using 3D printing to produce weapons and missiles is scary (“The gun lobby, which is supporting the ownership of fire arms, loves 3D printing”). Plans for printing a machine gun have been removed from the Internet at the request of US authorities. On the other hand, as shown by Wozniak et al. of Jagiellonian University in Poland, one can use the 3D printing to identify weapons used in commission of crime5.

Social changes

In the article "The consequences of 3D printing" Mary Gehl says that "the extraordinary possibilities of general household use of this technology have great potential to change the way in which the goods are manufactured, designed and innovated." The accompanying changes will affect not only the economy. Legal basis and sociological consequences may be similarly - but much deeply – affected as the changes introduced by the digital formats in the music industry since the ability to easily copy objects may violate all key areas of intellectual property rights, such as copyright protection of industrial designs, patents and trademarks.

We should also expect profound social change. In the first half of the twentieth century in advanced economies which are characterized by a large scale of production, consumption and standardized products, consumer society has been created. The produced goods could be purchased by workers who themselves become consumers. Henry Ford's black Model T was one of such products. Now modern society has evolved and “has given way in the 21st century to a paradigm characterized by small-batch production, economies of scope, specialized products, new information technologies, reliance on service jobs, and an emphasis on types of consumers rather than on social class.” This conforms to trends introduced by 3D printers making our economy more flexible and changing many of our contemporary social and economic relations on the global scale. Society moves from the world of passive buyers to one in which production and consumption are continuous and symbiotic. Consumerism changes into prosumerism, in which production and use of objects will not be separated, for example, when people will produce parts to repair their washing machine or refrigerator, or make a necklace. We will deal with a such situation when homeowners with solar panels sell their surplus of generated electricity. In general, different effects of 3D printing and social change it is expected to bring are difficult to overestimate.

Fig. 16. Paul McCartney and other printed objects in Aye Aye Labs. © J. Tomala

The outlook

The impact of 3D printing technology on everyday life will be huge. In the "The Economist" article mentioned above, the future consequences of 3D printing were compared to the industrial revolution associated with the invention of the steam engine, the printing press and the transistor. According to Mary Gehl, 3D printing is developing very rapidly and will reach a turnover of US$ 3.1 billion in 2016 and US$ 5.2 billion in 2020. Decreasing prices of 3D printers will be accompanied not only by the development of the industry but also by the "explosion of 3D printing at home ." One of the 3D printing gurus, Terry Wohlers of Wohlers Associates in Fort Collins, Colorado, USA, predicts that this technology available first to such diverse user groups as students, scientists, DIY enthusiasts, hobbyists, inventors and entrepreneurs, will become an important driver for the rapid development of 3D printing.

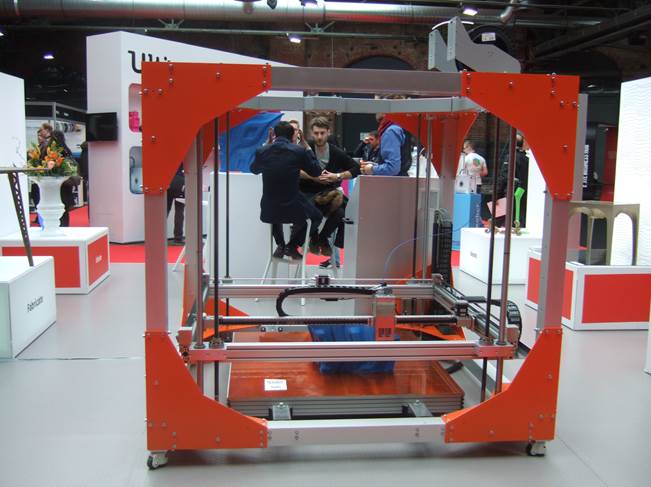

Fig. 17. Gigantic 3D printer BigRap at 3D Printshow 2015 in Berlin. © H. Dodziuk

And what is happening in this domain in Poland?

We do quite a bit. A number of companies producing 3D printers and/or offering the printing services have sprung up in several Polish cities and are taking part in specialized conferences and trade fair meetings in Poland and abroad. There are even specialized conferences. There are numerous internet shops selling the printers and a Zortrax store in Cracow while the Zmorph company from Wrocław opened its first showroom in Haarlem in the Netherlands. Leroy Merlin introduces 3D printing workshops in its supermarket chain. A 3D printer by the Polish company Jelwek was advertised last year as a Christmas gift. The company also created an elegant watch with 3D printed casing and bracelet marketed on their webpage https://jelwek.pl/pl/akcesoria/90-jelwek-watch.html for about US $80.

Fig. 18. 3D printed Watches by the Jelwek company. © Jelwek.

The greatest recognition in Poland and abroad, was received by the Zortrax company, that sold 5000 printers developed in Poland, but produced in China and Hong Kong, to the Dell corporation. Zortrax raised the capital for development on the crowd-sourcing Kickstarter platform, which also introduced Zortrax to Dell. Zortrax M200 printer shown in Fig. 1 won the first place out of 400 printers rated by users of 3DHubs community.

The most interesting applications of 3D printing in Poland include regenerative medicine. The first in Poland Laboratory of Individual Medical Implants in Łódź performed at least three operations in which the 3D printed portions of the skull were implanted. Surgeons from the Department of Maxillofacial and Plastic Surgery at the University Hospital in Białystok printed the parts of the mandible removed during surgery of 78-year-old cancer patient and doctors at the Military Naval Hospital in Gdansk carried out ENT (otolaryngological) operation previously rehearsed on the printed model.

To Summarize

Almost every day we are literally “bombarded” with information on new 3D printers, printing materials and application of 3D printing and the beauty of many projects and their effectiveness is captivating. It is not possible to foresee all economical and societal changes it will bring. However, it is clear they will influence all our lives.

References

(1) Murphy, S.; Atala, A. Nature Biotech. 2014, 32, 773.

(3) Chen, T.-H.; Lee, S.; Flood, A. H.; Miljanic, O. S. CrystEngComm 2014, 16, 5488.

(4) Toffler, A. Future shock; Random House, 1970.