In.var and re.var

|

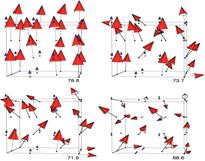

Invar is Fe-Ni, 65-35% alloy. Ab-initio calculations [1] showed that magnetic moments of nickel (blue

here) are aligned, while those of iron (red) seem to be chaotic. And

this disorder-in- order assures the minimum volume (and energy). Read below

|

|

INVAR Effect- after 100 years finally understood

In 1897 the Swiss physicist Charles Edouard Guillaume discovered that fcc Fe-Ni alloys with a Ni

concentration around 35 atomic %, now called INVAR, exhibit anomalously low, almost zero, thermal expansion over a

wide temperature range. This discovery immediately found widespread application in the

construction of calibrated, high-precision mechanical instruments,

such as seismographs and hair springs in watches. Today, Invar alloys

are used in temperature-sensitive devises,

such as shadow masks for television and computer screens. In 1920

Guillaume was awarded the Nobel Prize in Physics for the discovery of

these Fe-Ni alloys.

It was realized early on that the explanation of the Invar effect is related

to magnetism. Yet, though it has been 100 years since this effect was

discovered, it was not understood. In a recent article published in

Nature ''Origin of the Invar effect in iron-nickel alloys (Nature 400,

46 (1999)), I. Abrikosov and B. Johansson from Uppsala node of the

Network, in collaboration with Mark van Schilfgaarde from Sandia

National Laboratories, Livermore, USA, presented results of ab initio

calculations of volume dependences of magnetic and thermodynamic

properties for the most typical Invar system, a random fcc Fe-Ni Invar

alloy, where they allowed for noncollinear spin alignments, i.e. where

the spins may be canted with respect to the average magnetization

direction. They have found that the evolution of the magnetic

structure already at zero temperature is characterized principally by

a continuous transition from the ferromagnetic state at high volumes

to a disordered noncollinear configuration at low volumes, and that

there is an additional, comparable contribution to the net

magnetization from the changes in the amplitudes of the local magnetic

moments. The noncollinearity gave rise to an anomalous volume

dependence of the binding energy curve, and this allowed Mark van

Schilfgaarde, I. Abrikosov and B. Johansson to explain the well-known

peculiarities of Invar systems.

http://psi-k.dl.ac.uk/TMR1/summary_report.htm

The result on INVAR has been obtained within EU TMR

Network Ab-Initio Calculations of Magnetic Properties of Surfaces, Interfaces and Multilayers guided by prof. Walter from

Daresbury Laboratory, Warrington, UK

We thank for the permission.

|

Do you remember old spring-moved clocks? Their pendulum was attached

to thin, high-precision spings, made of INVAR. Old material, but new discoveries! |

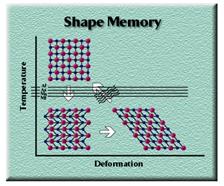

Some material shrink with temperature, another come back to their

old shape. We call them “shape-memory” alloys. |

|

|

|

Memory-shape flaps do not require huge hydraulic actuators but only heating wires. They are used in USA

military aviation from sixties Other applications of memory-shape alloys span from robot actuators, hydraulic fittings to medical

protesis. |

The most common shape-memory metals are Nickel-titanium 50-50 alloys or copper alloys, like CuZnAl,

and CuAlNi, but even Pt is used. The wire, twisted at low temperature, when heated will come back to the original shape.

And the “original” shape? It is fixed bending the wire at 500ºC. It can be bent and unbent a million times

|

|

In shape-memory alloys two sub-phases coexist: hard, high-T austenite and low-T, plastic

martensite. Cooling brings all austenite to martensite. Subsequent deformation keeps the martensite structure intact. It return to the

original austenite after heating. |

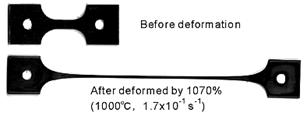

“Normal” material are subject to a permanent plastic deformation, once stress exceeds the limit of

elasticity. In shape-memory alloys, a thermal treatment, after the stress has been removed, brings the object to the original dimensions.

After: K. Ireland, University of Wollongong, Material Engineering |

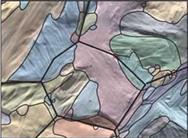

This (left) picture from Transmission Electron

Microscopy shows coexistence of martensite (long needles) and

austenite (patches) phases. In pure titanium only one phase exists (Scanning EM). |

|

This Fe-Cr-Ni-Mo dual-phase stainless steel elongates better than the chewing gum

And this “cosmic” rubber is soft, if torn slowly, but springs, if hit.

The Material Science came to the playground! |

|

|